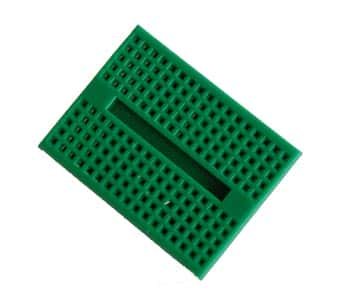

Breadboards are a simple solution for circuit building, especially when you need to prototype or test a circuit. Constructed of plastic, a solderless breadboard contains hundreds of spring-loaded connection sockets (also called tie points) which connect the leads for through-hole electronic components and 22 AWG wire to form an electronic circuit. One key feature of breadboards is that they require no solder to connect your components making testing or prototyping a circuit very quick and painless.

Breadboards are a simple solution for circuit building, especially when you need to prototype or test a circuit. Constructed of plastic, a solderless breadboard contains hundreds of spring-loaded connection sockets (also called tie points) which connect the leads for through-hole electronic components and 22 AWG wire to form an electronic circuit. One key feature of breadboards is that they require no solder to connect your components making testing or prototyping a circuit very quick and painless.

How do breadboards work?

A breadboard is constructed on hundreds of holes arranged in vertical and horizontal rows. The outer rows which run lengthwise across the circuit board are generally reserved for the circuit’s power supply. The interior rows of holes are where the electronic components are inserted. Each row of holes forms a node; that is, any components that reside on the same node will be connected when they are inserted into a hole in that same row, or node. This is because under each row is a copper plate that connects the holes to each other.