Solar radiation, as well as other solar resources like wind power, wave power and hydroelectricity make up over 99% of the renewable energy sources available to us. Amazing!

I remember reading about google’s goal of installing enough solar panels to generate electricity for 50,000 homes. They have made a real commitment to investing in renewable energy resources.

Imagine if we each made JUST ONE home appliance solar powered? We can start small – like a solar powered I-Pod charger or some solar powered outdoor lights. How about a solar powered cell phone charger? Once you realize how easy it is to begin using solar power, you’ll be ready to convert some of your bigger energy drains…..like maybe a hot water heater?

People are motivated to convert to solar power for a variety of reasons. Some look at the financial benefits while others are more concerned about the earth.

We all have been hit hard this year with rising fuel costs. My cars cost more to fill up, my home cost even more to cool down, and I just got a huge bill from my propane company. The only fuel source that cost the same this year as last is my solar bill. It’s still ZERO!

Although I personally got involved with solar energy for financial reasons, my focus has changed over time. I am glad to be doing just a little bit to reduce our dependence on non-renewable energy sources.

If you’re ready to take the plunge, take a look at our solar panels and solar controllers. Remember to take your time, do your homework, then be prepared to reap the benefits of solar power for years to come.

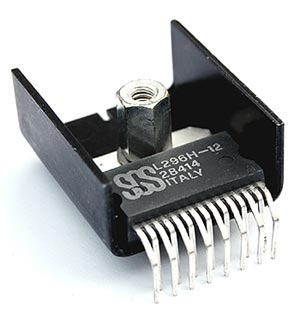

lot of study was done in the field and the initial operational amplifiers, based on vacuum tubes, were a result of the research done in Bell labs. By 1960’s, vacuum tube op amps had given way to solid state devices and hybrid operational amplifiers were entering the scene.

lot of study was done in the field and the initial operational amplifiers, based on vacuum tubes, were a result of the research done in Bell labs. By 1960’s, vacuum tube op amps had given way to solid state devices and hybrid operational amplifiers were entering the scene. Here are some other uses:

Here are some other uses:

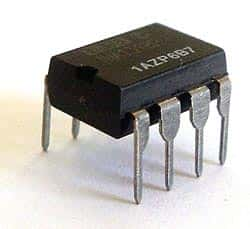

A digital potentiometer is digital equivalent of variable resistor potentiometer. It is a digitally controlled electronic component with built in IC or a digital to analog converter. It is widely used in instrumentation amplifiers. It has limitation of being restricted to currents of a few milli amperes and voltage in the 0 to 5V range.

A digital potentiometer is digital equivalent of variable resistor potentiometer. It is a digitally controlled electronic component with built in IC or a digital to analog converter. It is widely used in instrumentation amplifiers. It has limitation of being restricted to currents of a few milli amperes and voltage in the 0 to 5V range.